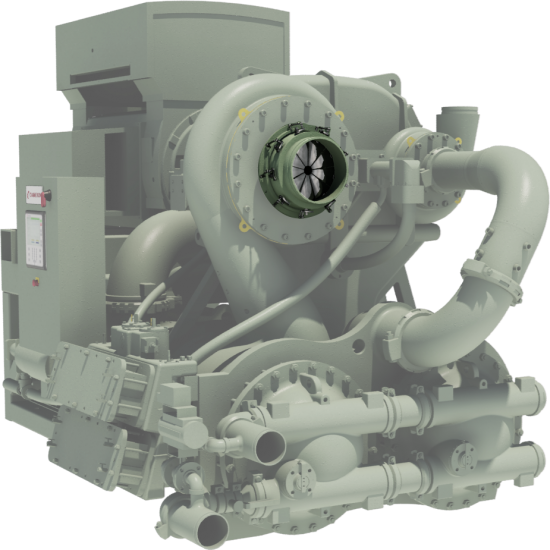

3 Stage Centrifugal Air Compressor

First stage compressor volute 03.

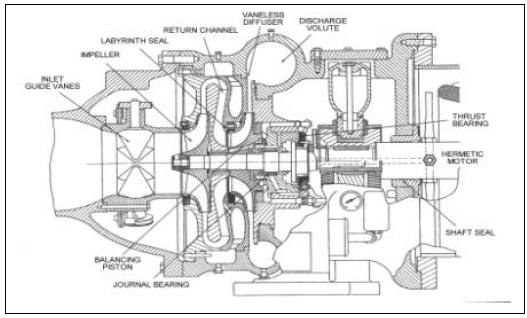

3 stage centrifugal air compressor. Engineered using innovative in house technology the zh centrifugal air compressor is the result of years of experience in the design of oil free air compressors we care about your air quality zh and zh oil free air compressors provide clean air with iso 8573 1 class 0 2010 certification. At times it can be 3 stage whose efficiency is higher than other positive displacement and screw types. The first part of the centrifugal impeller looks very similar to an axial compressor. Available in up to four stages centrifugal air compressors are on average 5 more efficient than older compressor.

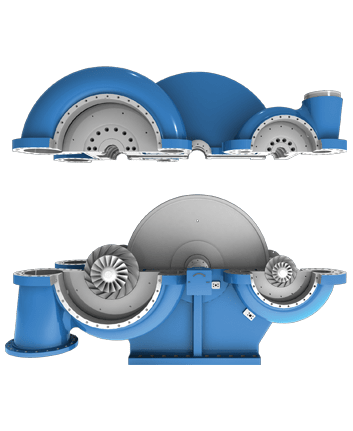

Air flow diagram 01. A single stage consists of one impeller. As air compresses the temperature increases and multi stage compressors take care of this issue by letting the air cool down. Coolant in 04.

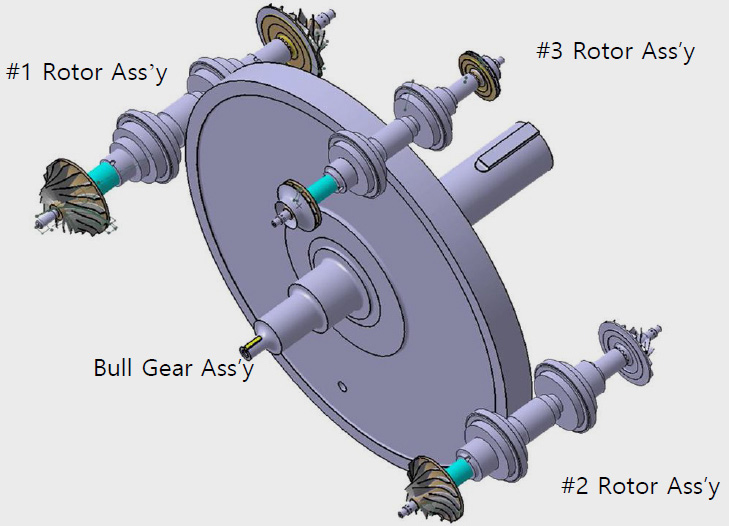

Centac c800 centrifugal air compressor. The addition of the turbo air and msg centrifugal compressors expands our market coverage to higher pressure higher flow and process gas compression applications. However given the same energy input the 3 stage compressor will output less compressed air than the equivalent sized 4 stage. Advantages of this arrangement include.

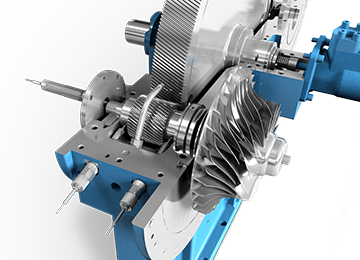

A 3 stage compressor is less mechanically complex than a 4 stage compressor. Msg process gas and api compressors. Reciprocating piston compressors use a cylinder to force air into a chamber where it is compressed. The simplest compressor designs feature a single cylinder chamber arrangement.

So what is surge anyway. Directed gas movement to reduce turbulence induced friction. While straightforward this setup is limited in its efficiency and capacity for delivering high volumes of pressurized air. The centrifugal air compressor can either be a single stage or multi stage.

Msg centrifugal compressors feature an advanced arrangement of gas flow components. Fs elliott air compressors take maintenance friendly operation a step further by offering a horizontally split gear case allowing full access to the gearbox in the field and avoiding costly downtime. Centrifugal air compressor performance curves. Typical 1 stage centrifugal air compressor curve.

It moves air up to 3 1 compression ratio for either vacuum or pressure duty. Both are shown in the adjacent photograph of an engine with 5 stages of axial compressor and one stage of centrifugal compressor. 3 stage vs 4 stage air compressors. In a three stage compressor the air will go into the first intake and be compressed before traveling over a cooler.

Air is cooled after every stage to provide high isothermal efficiency.